HOT-PROCESSED SAUCES

New food trends, new challenges, and how processing makes the difference.

From clean label to plant-based, from indulgent to functional: the hot-processed sauces segment is evolving rapidly.

Consumers demand more transparency, variety and nutrition, and expect the same product quality every time. The pressure is on:

- Less dairy, more alternatives

- Less additives, more naturalness

- Less compromise, more customization

But one thing remains: Your process must deliver – reliably and efficiently.

TRENDS ARE DYNAMIC. YOUR SETUP SHOULDN'T BE.

Whether you're adapting a classic béchamel or creating oat- or nut-based sauces – smart process design is key.

- Can your machinery handle viscosity shifts, ingredient variability, and thermal sensitivity?

- Can you scale while minimizing rework and preserving taste?

- Can your system switch between recipes with minimal cleaning time?

At ProXES, we understand food trends, but more importantly, we translate them into scalable, stable process solutions.

MACHINES THAT MATCH YOUR MISSION

COMBITHERM

All-rounder for flexible batch production with direct steam

→ For sauces that require strong heating and smooth transitions

✅ Efficiency, Flexibility, Output

TERLOTHERM

Scraped-surface heat exchanger for precise indirect processing

→ For sauces needing gentle, even heating without steam

✅ Quality, Sustainability, Efficiency

VACUTHERM

Perfect for home-style or roasted sauces with character

→ Fast, flavor-preserving cooking under vacuum

✅ Output, Profitability, Quality

UNIVERSAL MACHINE

Compact cooker for small batch or R&D

→ Ideal for testing new recipes and rapid changeovers

✅ Flexibility, Efficiency, Entry-Level Investment

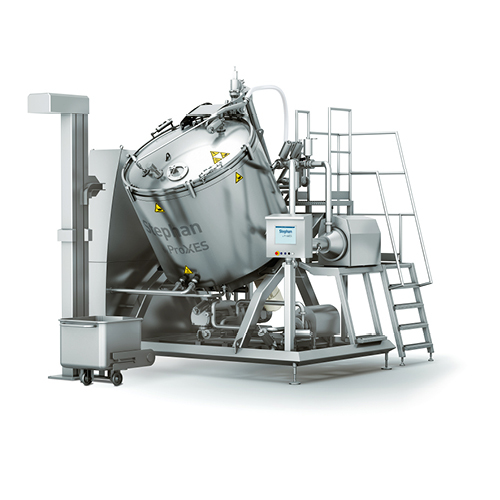

PROXX D

High-performance vacuum system with powerful homogenizer

→ For demanding emulsified sauces or continuous operations

✅ Quality, Output, Process Stability

JOIN THE WEBINAR – 30 MINUTES THAT BRING CLARITY

In our free session recording, we’ll walk you through:

- The role of ingredients, emulsifiers, and pH in processed sauces

- The impact of heating, shear, and process time on product quality

- The differences between batch and continuous production

- How to select the right setup: from test kitchen to industrial scale

Contact us today!

Please don't hesitate to reach out to us. If you have any additional questions, we are here to assist you and provide the information you need.

We look forward to meeting you and making your vision a reality.